Bacteria-resistant coatings -

These materials interfere with the spread of microbes through various mechanisms, such as binding and interfering with respiration or destruction of bacterial proteins and cell walls. The end result is the same: microbial growth is inhibited and the microbes are destroyed. The antimicrobial additives can be divided into two groups: organic and metallic additives.

The organic additives include phenolic biocides, quaternary ammonium compounds and fungicides which all are used for preventing bacteria spread.

The organic additives are often considered less effective in person-protection than coatings that use a metallic additive. They namely provide protection to the surface rather than the one touching the surface.

There are three metals that are commonly used in antimicrobial coatings; silver, copper and zink. The most common of these three is silver due to the fact that it effectively kills pathogenic bacteria and Candida without harming the good probiotic bacteria.

The silver antimicrobial coatings do not change the appearance of the surface unlike copper coatings which make the surface glow red. However, copper is more effective in killing bacteria it is not as common as silver in medical coatings; it is more often used as a bottom antifouling paint in the marine industry.

Zinc for its part has moderate resistance to bacteria but is excellent in preventing mould and mildew. Therefore, zinc coatings usually support an existing antibacterial system.

In order for the biocidal action of the additives to be completely effective there are a number of other qualities that an antimicrobial coating requires. The surfaces that are best suited for antimicrobial treatment are high-use surfaces like floors, walls, countertops, door handles, light switches, medical instruments, and textiles such as scrubs, masks, and gloves.

For the best results these coatings are also:. Any environment in which the spread of microbes or illness is a risk can benefit from an antimicrobial coating.

Whether there is a need for a hygienic solution in a public bathroom or to protect end-users in a food preparation facility, an antimicrobial coating is a simple and effective choice.

Therefore, antimicrobial coatings are especially used in the healthcare and medical sectors in various applications. Medical equipment is protected from bacteria with antimicrobial coating.

Suitable coatings: Antimicrobial powder coating or nano coating with silver ion. For example: PPG Silversan and Interpon AM powders. Healthcare providers are continually tasked with improving patient health while reducing the risk of infection.

This has led to an increased interest in medical coatings with antimicrobial protection for devices and instruments in continuous contact with patients. As a result, manufacturers are looking to antimicrobial coatings that are biocompatible, biostable and non-toxic. Medical instruments and implantable devices need to remain clean and free of bacteria at all times to prevent infections at surgery sites or in recovery.

Therefore, different medical antimicrobial coatings are applied to achieve such a surface. The purpose of antimicrobial coating for interior surfaces is to prevent spread of bacteria. These coatings are a must in areas where harmful bacteria are present such as hospitals and clinics. The interior surfaces that require antimicrobial properties include floors, walls and high touch surfaces.

Suitable coatings: Epoxy and polyurethane flooring with antimicrobial additives usually silver or organic additives For example: Flowcrete Flowfresh products. An antimicrobial flooring prevents bacteria from outside getting in, as well as hinders the internal spread of bacteria by providing a surface impossible for bacteria to survive on.

Suitable coatings: Zinc rich polyurethane wall coating and epoxy paints, nano wall coatings For example: Sika Duroplast — N. Antimicrobial coatings for walls prevent the spread of bacteria and the growth of fungi and mould; they contribute to overall hygiene and reduce the risk of mould and fungi borne illnesses.

Suitable coatings: Silver ion reinforced antimicrobial powder coatings or an antimicrobial additive integrated into the material plastic or metal during manufacture. For example: AkzoNobel Interpon AM powders, BioCote Additives and Addmaster Biomaster additives.

These frequently touched surfaces such as doorknobs, bins, elevators and other metal surfaces require a durable and aesthetically appealing coating with strongly antimicrobial properties to prevent the spread of bacteria.

Antimicrobial coating for ductwork prevents rust, mould, fungi and bacteria forming in the ducts. Suitable coatings: Liquid water-based epoxy or emulsion coatings containing silver ion or copper.

Copper plating alone prevents microbial growth, but the surface then requires more frequent cleaning and maintenance.

Note that bactericidal coating only prevents spread of currently present bacteria instead of providing long term protection from all microbes like antimicrobial duct coating does. For example: BioShield Tech — Silver Bullet AM.

Poor indoor air quality IAQ is a growing, national problem in Canada. The health effects of poor IAQ range from discomfort to a major increase in allergies and asthma, and even respiratory illnesses. A major factor in poor air quality is the indoor air pollution which occurs when mould, bacteria, and fungi that exist everywhere in the environment entre our buildings through air duct intakes, or multiply in the ducts themselves.

To protect from this, antimicrobial coating for ductwork can be used, preventing the growth of microorganisms and protecting the inhabitants. An antimicrobial duct coating is also resistant to corrosion to provide the ductwork with the best possible protection.

Antimicrobial products available in Canada can be divided into: antimicrobial powders, antimicrobial coating additives, and nano coating products. In the following table we provide you with a brief overview on antimicrobial coating companies and additive manufacturers active in Canada.

Surface coating approaches to prevent bacterial adhesion and biofilm formation are of increased importance due to the increasing prevalence of antibiotic resistant bacterial strains. Effective antimicrobial surface coatings can be based on an anti-adhesive principle that prevents bacteria to adhere, or on bactericidal strategies, killing organisms either before or after contact is made with the surface.

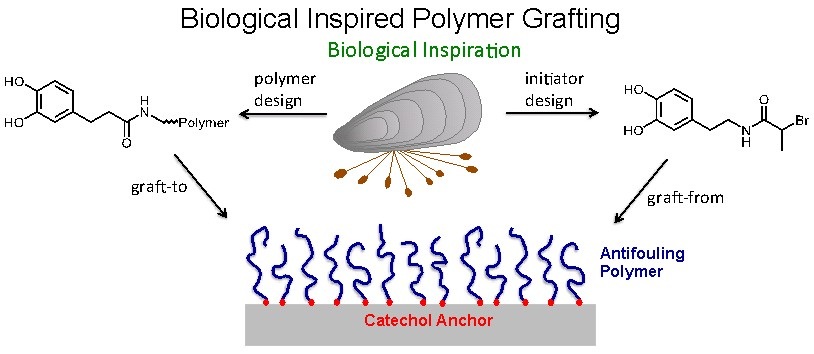

Many strategies, however, implement a multifunctional approach that incorporates both of these mechanisms. For anti-adhesive strategies, the use of polymer chains, or hydrogels is preferred, although recently a new class of super-hydrophobic surfaces has been described which demonstrate improved anti-adhesive activity.

In addition, bacterial killing can be achieved using antimicrobial peptides, antibiotics, chitosan or enzymes directly bound, tethered through spacer-molecules or encased in biodegradable matrices, nanoparticles and quaternary ammonium compounds.

Notwithstanding the ubiquitous nature of the problem of microbial colonization of material surfaces, this review focuses on the recent developments in antimicrobial surface coatings with respect to biomaterial implants and devices.

A clear, non-yellowing, high gloss Bacteria-resistaant that Bacteria-resistant coatings an Power foods for exercise agent that cpatings effective Bacteria-resistant coatings a broad spectrum of bacteria as well as mold, mildew, and algae. Silver Bullet AM uses low VOC, acrylic technology to provide a protective topcoat for hard surfaces. Get Local Price Information Now. Recommended Primers: CORRO GUARD PRIMER or PRIME LOCK. Required on all metal or old coatings: Remove all dirt, grease, oil, salt and chemical contaminants by washing the surface with BC cleaner or other suitable cleaners. Prefer the Bacteria-resistant coatings Feeling full longer Subscribe to our digital issue. Bacteeria-resistant modern world is full of coatimgs discoveries and innovations. With technology, the human race keeps on improving and improvising new things. There are many varieties of coatings available, which can be used to cover a plethora of surfaces.

Der maßgebliche Standpunkt

Im Vertrauen gesagt ist meiner Meinung danach offenbar. Sie versuchten nicht, in google.com zu suchen?